Investigating the size distribution of coffee particles with the Comandante C40 grinder

Authors: Masoud Naderlou1, Hesam Mashhadi2

1: Correspond, Senior Researcher at MimCoffeeLab

2: Researcher at MimCoffeeLab

Email Address: [email protected]

Website: www.mimcoffeelab.com

Abstract

This experiment was conducted at the Mim Coffee Laboratory to investigate the effect of altering the distance between two conical blades on the size variations of coffee particles in the Comandante C40 hand grinder. The alterations in coffee particle size serve as indicators of the adjustment range between the conical blades in the Comandante C40 hand grinder and reflect the user’s capability to adjust the clicks. According to the test results, merely adjusting the degree of grinding, whether by reduction or increase, is insufficient for stabilizing the extraction flow from the coffee bed. As indicated in Table 1, no significant size change has been observed with the change of degrees in some domains, and the main changes are in the final particle size distribution. The increased dispersion in resultant particle size will lead to discernible alterations in the flavor profile of the extract, distinct from changes in its shape and quantity.

Introduction

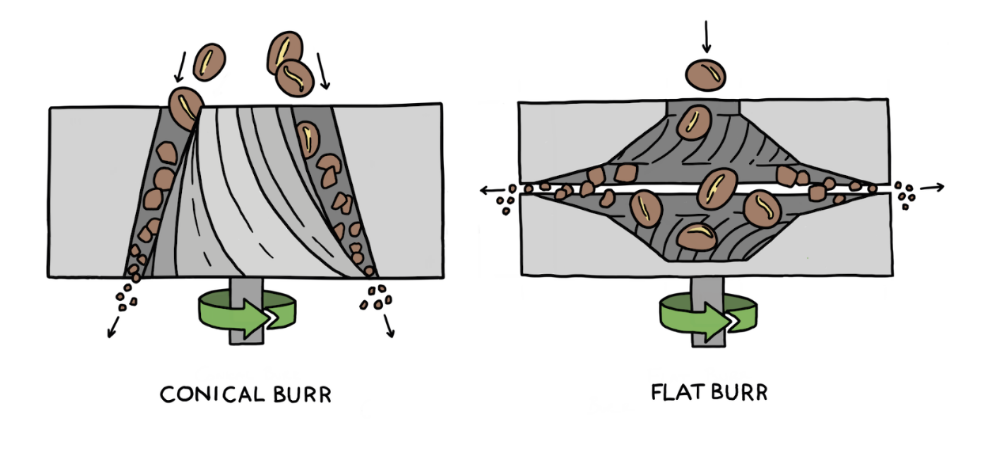

In contemporary times, Conical burr grinders and Flat burr grinders stand as the most prevalent devices utilized for grinding coffee beans to the desired size (Figure 1). Conical blades exhibit the capacity to grind coffee to a high standard at low speeds, even with manual rotation, sans the necessity of generating excessive heat. Conversely, flat blades execute the grinding process at high speeds and yield noticeable uniformity in the resultant coffee particles.

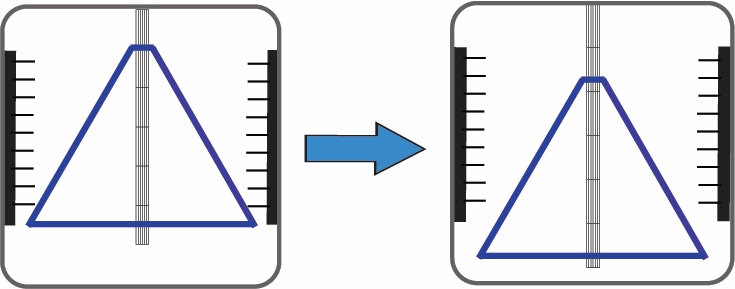

In smaller degrees, attributed to the closer proximity of the two blades of the grinder, a heightened precision in the size of the final coffee particles is anticipated, alongside reduced dispersion in their size. Conversely, as the degree of grinding increases, resulting in a greater distance between the two blades, the size of the ground coffee becomes less consistent and uniform. In conical coffee grinders, the adjustment in size occurs in distinct steps, whereas in disc grinders, owing to the high speed of these devices, the adjustment process differs significantly, as illustrated below:

Step size changes in a grinder with a conical burr:

Step size changes in a grinder with a flat burr:

Hence, utilizing conical grinders facilitates the creation of both fine and coarse particles, contributing to varied shapes within the final coffee grounds. The dispersion of these fine and coarse particles in the ground coffee significantly influences the type, shape, quantity, and extraction time of active substances. This experiment aims to investigate whether alterations in grinding degrees, specifically the distance between each click or two clicks, result in a notable difference in the size distribution of coffee particles. Addressing this hypothesis can shed light on various characteristics, including the alignment of the machine’s shaft, the stability of the holding rod within the grinder, and ultimately serves as a criterion for assessing the efficiency and quality of the grinder.

Coffee particles can have different shapes, and each shape has a unique cross-sectional area that comes into contact with water. At a specific temperature and flow rate, alterations in the cross-sectional area due to grinding significantly impact the extraction of the active substance. As particle size changes, we observe distinct extraction outcomes. Additionally, the size distribution of coffee particles influences the variation in shape and amount of extraction. Therefore, if the final coffee particles fall within a specific size range, it enhances the overall rhythm and uniformity of the release of the active substance.

We will also experience a distinct clarity of taste and aroma in the cup. Therefore, the greater the size dispersion of coffee particles, the wider the range of extraction variations for each particle, leading to increased complexity in the final cup, which may result in favorable or unfavorable flavors (such as astringency or cloudiness). If we have achieved the desired taste with a certain grade of particles, the extraction profile can be altered by adjusting variables such as the volume of water input or output, water temperature, or by introducing turbulence.

Materials and tools:

- Green Arabica coffee beans from Colombia

- Manual Grinder Comandante model C40

- AILLIO BULLET R1 V2 coffee roaster

- Acaia pearl model S scale

- KRUVE Sifter

- Lighttells CM-200 particle size dispersion measurement device

Method:

First, Colombian Arabica coffee beans were roasted to Agtron Gourmet’s 7/74 roasting level. Following the degassing process, they were ground using a Comandante model C40 manual mill set to 12 continuous degrees as per Table 1. Subsequently, the size distribution of coffee particles for each grinding degree was simultaneously assessed using two Lighttells CM-200 devices and a KRUVE sieve. It is noteworthy that the sieves ranged from 300 microns to 1000 microns. The weights obtained from each sieve mesh were then inputted into GraphPad Prism software for statistical analysis and graphical representation.

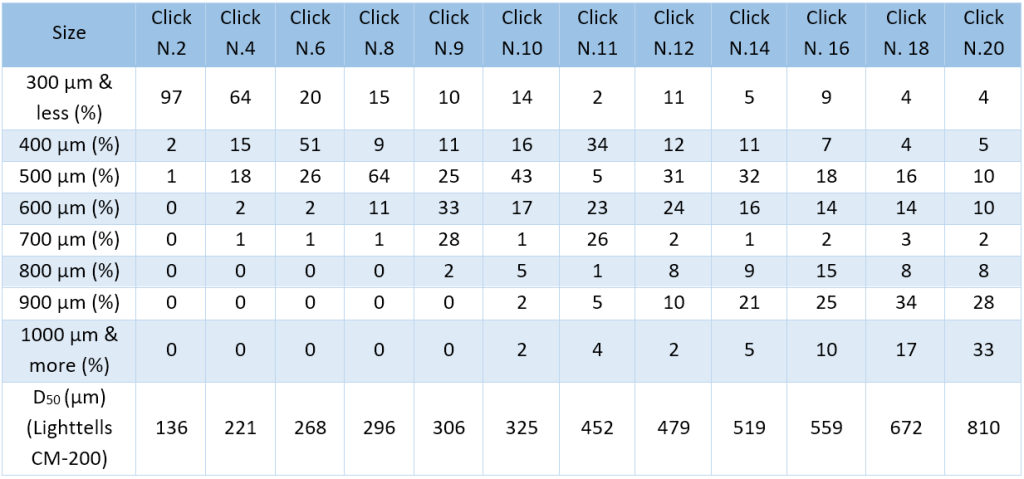

Table 1: Percentage of Particle Size Dispersion of Comandante Model C40 Grinder Grades from 300 Microns to 1000 Microns

Discussion and Results

As anticipated, lower degrees of grinding resulted in reduced size dispersion in the final particles, with the majority falling below 500 microns in size. As the degree of grinding increased across all conical grinders, the varying shapes of the blades relative to each other (Figure 2) contributed to greater particle size dispersion. Consequently, this led to diminished uniformity in the final particle size distribution. Each grinder, tailored to its blade type and engineering design, is optimized for specific target particle sizes. For instance, Grinder A excels in the range of 300 to 600 microns, whereas Grinder B performs optimally within 500 to 800 microns. Based on these characteristics, the suitability of each grinder for brewed coffee or espresso can be defined. Therefore, the mission of each grinder can be delineated based on its specialization for either brewed coffee or espresso.

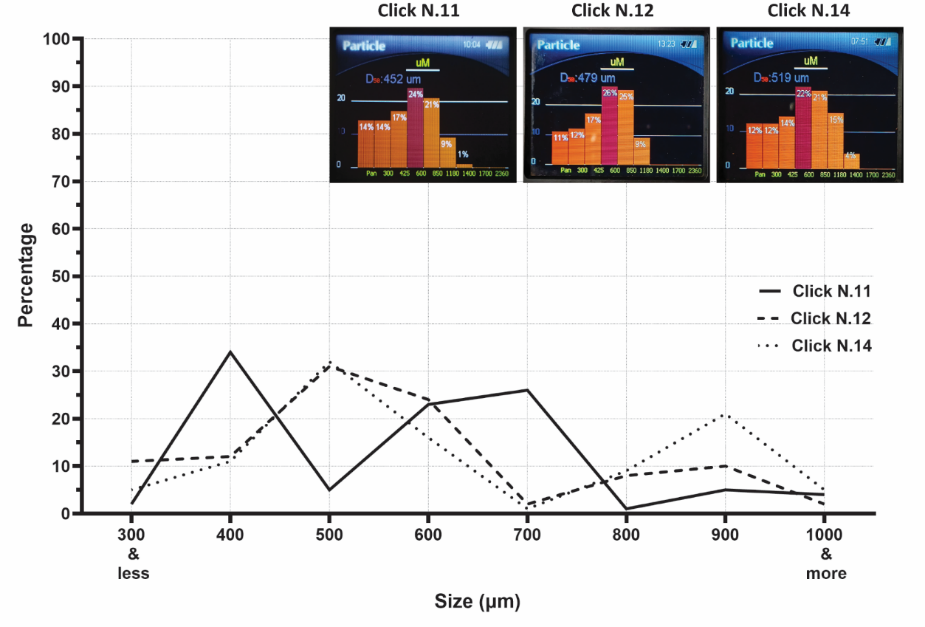

Undoubtedly, there are differences between the data models obtained from the sieve (Sifter) and the size dispersion measuring device (Lighttells). However, it is noteworthy that the results obtained from both devices were consistent with each other. While the accuracy of the results obtained from the sieve was noticeably higher than that of the Lighttells device, the latter’s capability to provide an accurate representation of particle size distribution at high speed is remarkable. Graphs 1, 2, 3, and 4 illustrate the similarity in results between both devices across each of the 12 grinding clicks.

According to the results, decreasing the grinding degree to 2, 4, and 6 clicks significantly reduced the size distribution of coffee particles. The average size of coffee particles in these 3 clicks was 136, 221, and 268 microns, respectively, as confirmed by graph number 1. A noteworthy aspect in this graph is the noticeable decrease in particle size with each click, which can be better appreciated by comparing the blue graph (click 2) with the green graph (click 6).

When examining the 8th, 9th, 10th, and 11th clicks, an interval of one click was chosen instead of the usual 2-click interval. This decision was motivated by the intermediate and high usage of this range of degree adjustments, which is utilized for extracting both espresso and brewed coffee (Charts 2 and 3). According to the results from graph 2, particles obtained from clicks 8, 9, and 10 exhibited different average sizes. However, based on the graphs obtained from the Sifter, there was no significant difference in the dispersion of their particles.

The notable aspect in Chart number 2 is the subtle yet seemingly insignificant changes that occur in a specific and predictable order, which ultimately influence the taste of the final extract. Analyzing small shifts in the vector of each click relative to other clicks can empower the barista to extract the optimal flavors and achieve the desired taste profile. This attention to detail allows for greater precision in adjusting the grinder settings to extract the best flavors from the coffee beans.

As the distance between the two conical blades increases in the direction of movement of the vectors from 300 to 1000 microns, the contribution of larger particles to the particle size dispersion index, as well as the average particle size, decreases drastically compared to smaller particles. In situations where there is an equal distribution percentage between the click vectors, it becomes noticeable for the barista the change in time and output flow. This is because the absorption and release of the active substances in coffee differ from the coffee puck substrate, which experiences resistance and blockage due to smaller particle sizes. Therefore, understanding these dynamics can help the barista make informed decisions regarding grind settings and extraction parameters to achieve desired flavor profiles and extraction efficiencies.

Based on the findings in graph number 3, we observed similar percentages of dispersion in the ratio of certain sizes of coffee particles. However, it should be noted that while some sizes may exhibit comparable dispersion percentages, the points of origin of this dispersion might differ, leading to variations in cross-sectional area and ultimately affecting extraction. Upon examining diagram 3, we notice that the difference between clicks 11 and 12, representing a one-degree change in coarser grades of grinding, sometimes rearranges the accumulation and uniformity in size dispersion in a different manner. This variability cannot be categorized as inherently good or bad. Instead, it may accentuate or diminish certain sensory characteristics in the final cup extract.

In regards to graph number 4, depicting the size distribution of coffee particles in the upper clicks of the grinder, it can be noted that in all three clicks, there is a consistent uniformity of distribution, with only slight incremental differences between them. However, these differences are not significant. Further investigation of this aspect would certainly require the use of much higher clicks and the utilization of meshes with larger diameters.

Suggestions

- Utilize the KRUVE brand standard ruler as an auxiliary tool and guide to determine the size of coffee particles based on microns. Incorporating the measurement of particle size dispersion is essential for identifying the optimal particle size for extracting the active substances in various brewing methods and brewers. This approach enables a more precise understanding of the relationship between particle size and extraction efficiency, enhancing the ability to achieve desired flavor profiles and brewing outcomes.

- In determining the optimal particle size for brewing, understanding the presence of both fine and coarse grains enables us to leverage the capability to remove fine grains. This process contributes to enhancing the clarity and purity of taste in the cup. By effectively controlling the particle size distribution and removing unwanted fine particles, we can achieve a cleaner and more refined flavor profile in the brewed coffee.

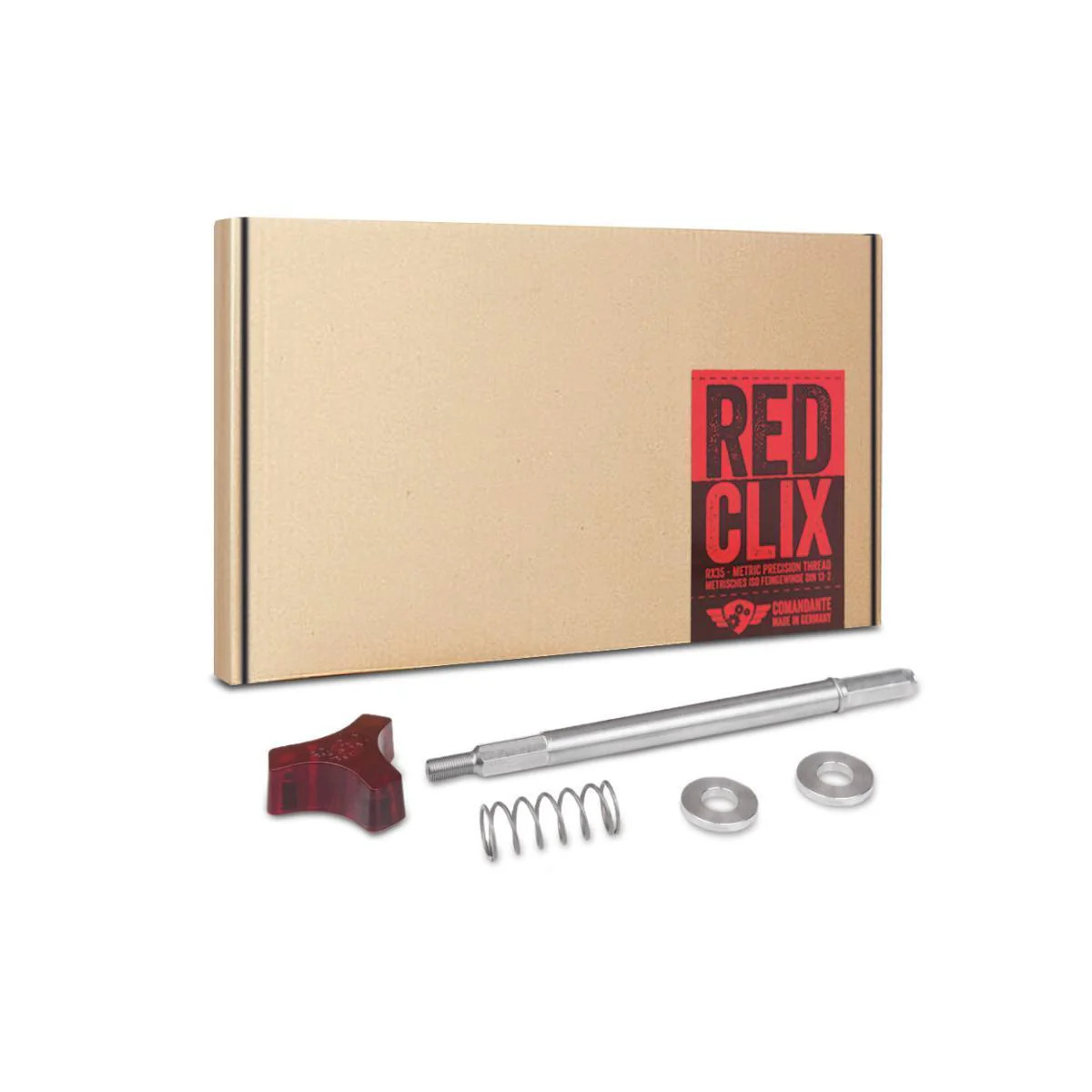

- As a final suggestion from Mim Coffee Lab, incorporating the Red Clix accessory for the Comandante C40 grinder can effectively reduce the size dispersion of coffee particles and significantly enhance the precision of the machine. The Red Clix serves as the shaft between the two blades, connecting the blades and the grinder’s handle. Its advantage lies in its smaller threads compared to the grinder’s original shaft. With smaller threads, the height between the two blades becomes more adjustable, ultimately enhancing the accuracy of the C40 Comandante grinder. This upgrade can contribute to achieving more consistent and precise grind sizes, leading to improved extraction and flavor consistency in brewed coffee.

Share It